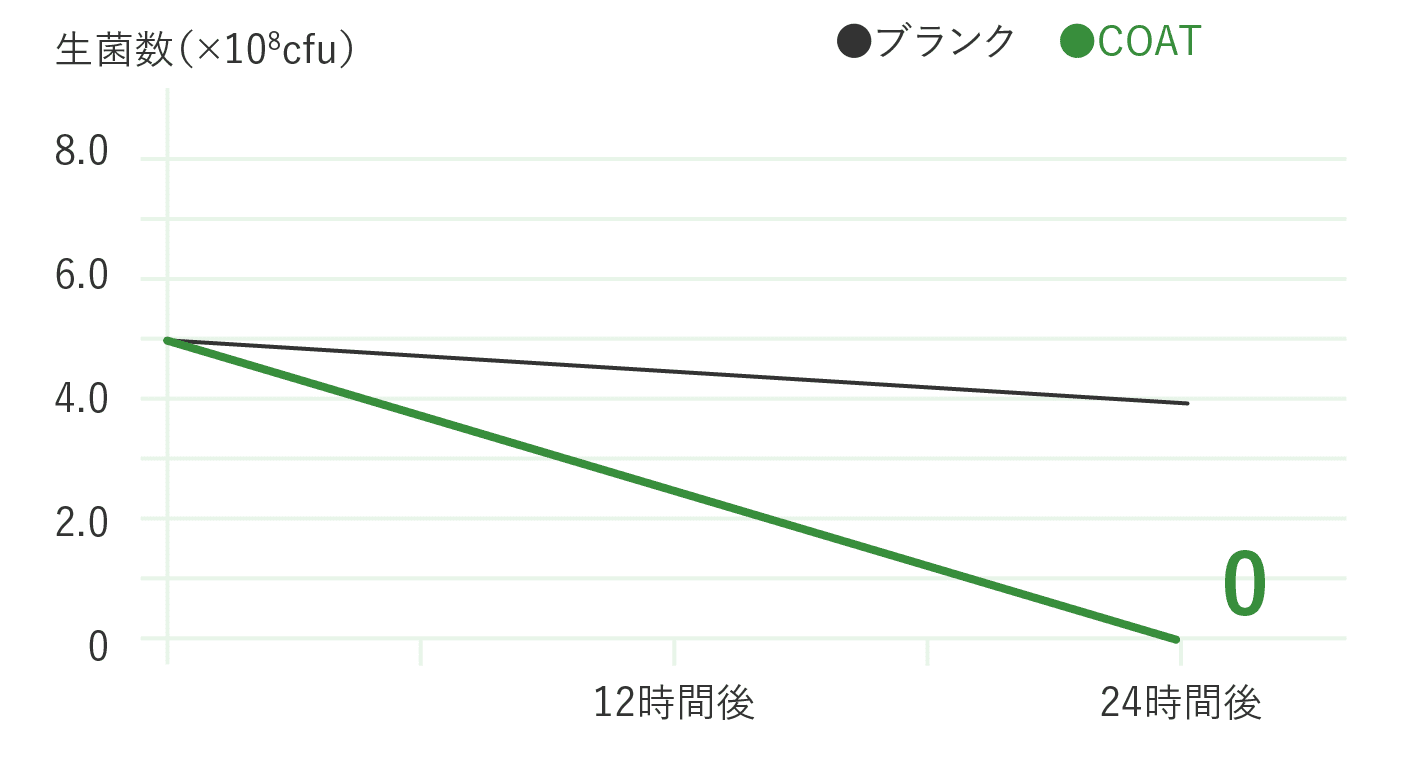

Up to 181 times more effective than other products.

While there are similar products available, their effectiveness is nowhere near that of COAT.

With data from Environment Ministry standards, we compare COAT effectiveness in the removal of vehicle exhaust gas (Nitrogen Oxides) with roadside poplar trees.

| Product |

Area

(m²) |

Nitrogen Oxide

(g/m²) |

Equivalent in Poplars

(No. trees) |

| Company A, Product E |

1,000 |

※1.00μmol |

34.6 |

| Company T, Product E EX |

1,000 |

0.052 |

95.0 |

| Company T, Product H |

150 |

0.057 |

15.0 |

| Company K, Product F |

1,000 |

- |

25.0 |

| Company S, Product D |

160 |

0.077 |

21.0 |

| Company D, Product S |

200 |

※0.56μmol |

2.4 |

| COAT |

1,000 |

※8.62μmol

0.248 |

435.0 |

* Calculated assuming a nitrogen oxide concentration of 1 ppm, and photocatalyst area of 0.005 sq. m. for 5 hours (JIS standard testing methodology).

Research Institute: General Incorporated Foundation of Japan Environmental Management & Technology Center (EMATEC)

The results show that COAT is more effective than other products by a factor of between 4.6 and 181.

Stadium

Stadium Hospitals and

Hospitals and Educational

Educational Hotels and other lodgings

Hotels and other lodgings Apartments and housing

Apartments and housing Bathrooms and wet areas

Bathrooms and wet areas Smoking rooms and toilets

Smoking rooms and toilets Private automobiles and taxis

Private automobiles and taxis Passenger trains, airplanes and ships

Passenger trains, airplanes and ships Restaurants and shops

Restaurants and shops Animal husbandry facilities

Animal husbandry facilities